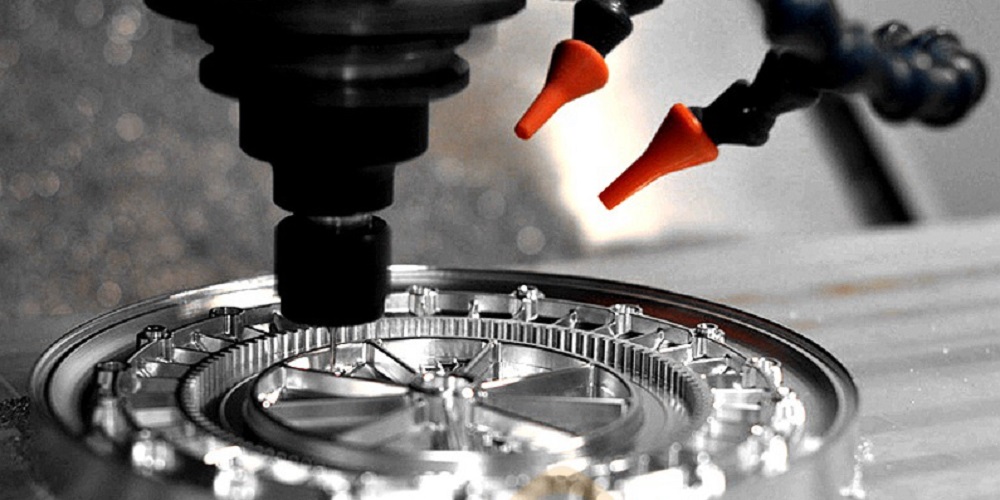

CNC machining is a widely used advanced process for making various machines, parts and prototypes. Sometimes, new samples are manufactured through this process to check their viability. This process makes it easy to calculate the cost of CNC machining. The budgeted expenses and originally incurred costs are compared with each other. Then you can manage the costs precisely and accordingly.

The computerized manufacturing process has helped a lot in the rapid production of prototypes with a high-efficiency rate. This controls cutting and grinding machines that help carve and manufacture new devices.

Pre-production budgeting:

Before making a new sample or product, scientists tell about the required material. However, the accountants help in determining the cost of the production per unit. The estimated charges include the cost of operating a CNC machine and raw materials for new prototypes. The cost of factory overheads per prototype production unit is also considered to determine the overall cost better.

Actual cost:

After producing a sample, it is easy to calculate the total cost. The incurred cost may increase the estimated cost due to several factors, some of which are as follows;

- Expensive (sometimes unchecked, obsolete) raw material

- More processing time than the estimated time

- High volume production in the beginning

- Difficult designs

- Multiple finishing of a single product

Then the accountants and scientists work together to omit extra raw materials and to reduce the cost to the highest possible level.

Steps to reduce the cost:

Cheap and good quality raw material is necessary to keep the cost minimum. For example, the price of stainless steel is 3 to 4 times higher than the exact size of aluminum metal. It depends on the type of product being manufactured that which metal is required. But in each case, it is necessary to fetch out less-expensive materials. It is the type of material that decides the processing time in the CNC machine.

Furthermore, complexity in the designs also dramatically increases the manufacturing time and, ultimately, related overhead costs. So, scientists should choose simple designs with fewer angular annotations and pits to make processing easier. It is recommended that one should use low-volume production parts to reduce the cost.

The finishing of the product (machine) is mainly done with a lot of precision to make it survive in harsh environments. For this purpose, multiple finishing is done; however, this is not an excellent way to economize the process. High-quality anodizing aluminum can give a better finish, which may help in better cost management.

Conclusion:

While manufacturing new prototypes, it is not advisable to expense the entire cost. Instead, research costs should be expensed out, while development and production costs are capitalized in the cost of the product. This gives a better display of the cost per unit of the manufactured prototype. In the end, the production department will exhibit the total cost of production, regardless of research cost, incurred in the beginning.

Reducing research and development costs is necessary to make the process and product viable in the market.